Update after one year of RE:Spin project

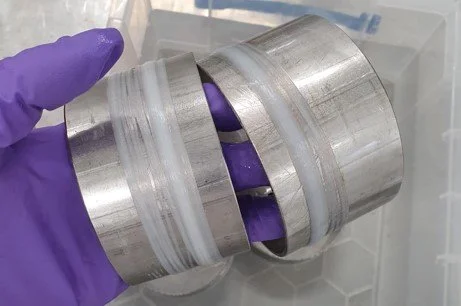

Recycled viscose spun from post-consumer waste (left) and pre-consumer fabric (right).

The project RE:Spin started approximately one year ago with the intention of developing a new textile recycling technology in which fibers can be directly respun from waste textiles. RISE was tasked with developing the new spinning process based on the dissolution technology developed previously by ShareTex. The project received funding from the strategic program BioInnovation and counts with the participation of Lund University, H&M Group Circular Innovation Lab and Valmet as well.

We are pleased to announce that the development activities are going well and that the project group has been able to spin recycled fibers from viscose waste. These fibers had only minor differences compared to those spun from control materials, which indicates that this technology could be applied to post-consumer waste (the stream most difficult to recycle) without any major obstacles.

The recycled fibers had an acceptable quality to be used in certain textile applications, which showcases the possibility to create a new textile-to-textile value chain with less intermediate steps between waste and recycled fibers.

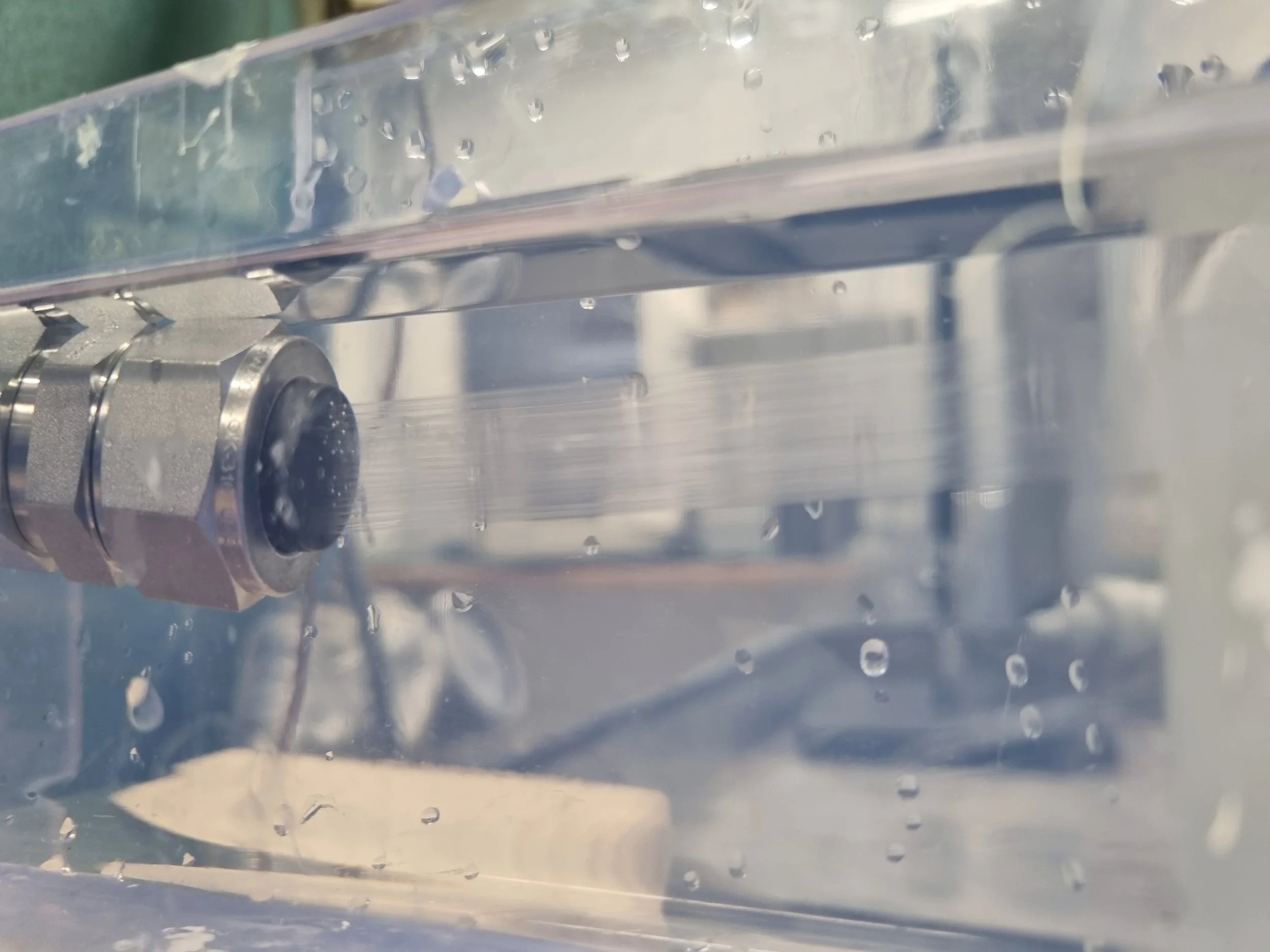

The properties of the recycled fibers can be further improved as spinning processes are not easy to tune and therefore the optimization work at RISE is still ongoing. As Jenny Bengtsson, researcher at RISE, said: “What is both challenging and fun about wet spinning is that each mixture of polymer and solvent produces a new behavior and thus the process must be adapted accordingly. This system requires, for example, that we combine experience from working with highly viscous polymer solutions suitable for air-gap spinning together with traditional wet spinning”.

The project group is highly encouraged by the results so far and, especially, of their implications since other innovators struggle to recycle man-made cellulose fibers such as viscose due to the low molecular weight of the fibers. The key aspect of this technology is that it mantains the molecular weight of the fibers, minimizing the loss of mechanical properties during the recycling, which allows for the recycling of viscose waste. The extrapolation of these results to another material, cotton waste, could have even more interesting implications: cotton could be recycled into a new fiber type whith almost identical (chemical) properties as the starting material. This possibility could change completely the paradigm of cotton recycling, in which cotton is transformed into other fibers (lyocell or viscose), and it is planned that RISE will begin trials with cotton waste in the first months of 2024 to evaluate this possibility.

Coagulation bath where recycled fibers are being spun.

The effective collaboration between the project partners is quickly transforming an idea into a proof-of-concept at lab scale. The combined experience of all the project partners is opening the door to a streamlined recycling process with minimal intermediate steps and recycled fibers with similar properties as the starting material. In the words of Edvin Bågenholm-Ruuth, PhD student at Lund Univeristy: “In our previous work, we have been researching different pathways to recycle textile waste. All of these pathways have involved some sort of intermediary product as a stepping stone for further valorization. What is exciting about this project, however, is that we can skip that intermediary step completely and go straight from waste to product. That is great from a process economy perspective but also a recipe of the technology’s flexibility”. We can only say that every partner is excited to see what the next, and final, year of the project will bring.

The project group of RE:Spin is coordinated by ShareTex and participated by RISE, Lund University, H&M Group Circular Innovation Lab and Valmet. We want to thank BioInnovation, a strategic innovation program financed by Vinnova, Energimyndigheten and Formas, for the financial support.

For more information about the project, please contact the project manager, Miguel Sanchis Sebastiá, at miguel.sanchis@sharetex.com or visit https://www.bioinnovation.se/en/projekt/respin-a-new-technology-to-expand-recycling-of-cellulosic-textile-fibers/.